Best Practices for Displaying Forklift Vehicle Security Check In Industrial and Stockroom Setups

The implementation of effective forklift truck safety and security signage is vital in industrial and warehouse atmospheres, where the risk of mishaps can significantly affect both personnel and procedures. Trick factors to consider such as exposure, positioning methods, and adherence to regulatory standards are vital for taking full advantage of the performance of these indications. In addition, the recurring maintenance and periodic evaluation of signage can further enhance safety actions - Forklift Truck Safety Signs. Nonetheless, the genuine obstacle lies in balancing these aspects to cultivate not only conformity but also an aggressive society of safety and security. What certain strategies can companies embrace to ensure their security signage truly offers its function?

Relevance of Safety And Security Signs

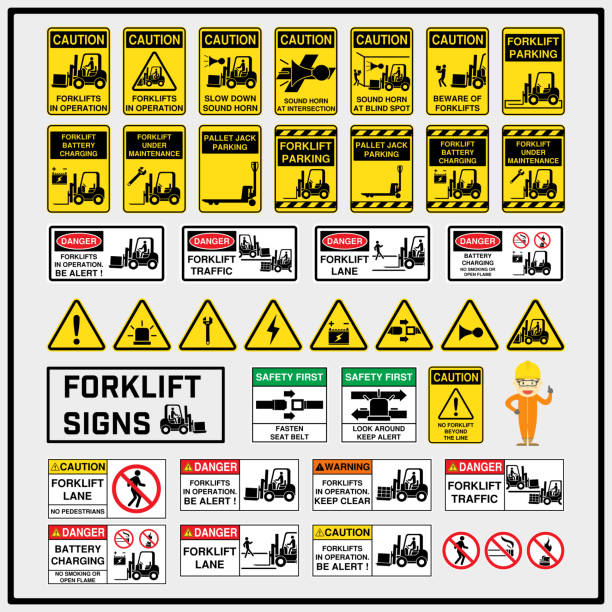

The relevance of safety signs in settings where forklift vehicles operate can not be overemphasized, as these signs play a vital role in preventing mishaps and making certain the safety and security of personnel. Efficient safety and security signs functions as an essential communication device, sharing important information regarding possible hazards connected with forklift operations. This consists of cautions concerning pedestrian zones, speed limits, and designated forklift routes, which are necessary for keeping an organized and secure workplace.

Correctly shown safety and security indications can improve situational recognition amongst employees, reminding them of the threats associated with their environments. They offer clear directions on secure practices, such as putting on ideal personal safety devices (PPE) and sticking to functional guidelines. Furthermore, safety and security signs contributes to conformity with regulatory requirements, aiding companies stay clear of penalties and advertise a society of safety - Forklift Truck Safety Signs.

Along with their preventative role, safety indicators cultivate a sense of responsibility amongst staff members. When workers recognize safety protocols and the potential effects of overlooking them, they are more probable to take aggressive procedures to safeguard themselves and their associates. Consequently, investing in high-quality safety signage is essential for any office where forklift vehicles are in procedure.

Key Presence Aspects

Effective exposure is extremely important in making certain the safety and security of both forklift drivers and pedestrians in busy job environments. To attain this, several key exposure aspects have to be thought about when making and placing safety indications.

First, the size and font style of the text on the sign play an important function. Larger font styles boost readability from a range, permitting people to quickly comprehend the message. Additionally, the use of vibrant and clear fonts can considerably improve legibility under various illumination conditions.

Reliable Positioning Methods

Indicator positioning considerably influences their efficiency in communicating safety and security messages within forklift procedures. To make best use of presence and comprehension, indicators need to be strategically positioned in locations where forklift task prevails. Key areas consist of junctions, unseen areas, and near loading and discharging zones, where drivers and pedestrians connect regularly.

Elevation is an additional vital factor; indicators must be put at eye level to ensure they are conveniently seen by both forklift operators and ground employees. Additionally, making use of contrasting colors and clear graphics will certainly improve presence, especially in low-light conditions or high-traffic locations.

Consider the flow of web traffic when determining placement. Signs should be positioned to assist drivers safely and successfully with the workspace, minimizing the danger of crashes. Regular evaluations should be performed to make certain that indications remain unhampered by equipment or stock, as changing designs can diminish their efficiency.

Including feedback from employees relating to indication positioning can likewise result in improvements. Involving personnel in this process fosters a culture of safety and security and recognition, inevitably adding to a much more safe and secure workplace. By carrying out these effective placement approaches, companies can improve communication and adherence to safety and security link protocols.

Compliance With Rules

Ensuring conformity with guidelines is essential for maintaining a risk-free workplace in forklift procedures. Regulatory bodies such as the Occupational Safety and Wellness Management (OSHA) and the American National Criteria Institute (ANSI) develop guidelines that dictate the correct usage of safety and security indications. Adherence to these guidelines not just advertises security but also alleviates the risk of charges and lawful obligations.

Forklift safety and security indications need to be plainly noticeable, understandable, and purposefully put according to regulative demands. These indications ought to utilize standard icons and shade codes to convey critical info effectively. Yellow suggests caution, while red signals risk, guaranteeing that workers can swiftly analyze the indicators in high-stress scenarios.

Organizations ought to perform routine audits to verify that all safety signs meets existing lawful criteria. By making sure that forklift safety indications adhere to mandated standards, companies cultivate a culture of security awareness amongst employees, consequently boosting total work environment safety and security and efficiency.

Routine Maintenance and Updates

Maintaining and upgrading forklift security indications is critical for guaranteeing that they stay effective and relevant in the office. Normal inspections should be conducted to analyze the condition of safety indications, as direct exposure to harsh industrial atmospheres can result in fading, damage, or obsolescence. Signs that are no more understandable or that have outdated details can significantly threaten security methods.

It is necessary to establish a routine upkeep routine that includes inspecting the presence and clearness of all safety and security signage. Any indicators that are put on, harmed, or misaligned should be promptly replaced or rearranged to keep their performance. Furthermore, as guidelines and security requirements develop, it is vital to upgrade signs to show current practices and compliance requirements.

Involving employees in security training sessions can likewise strengthen the relevance of keeping and updating safety and security indications. This not only makes sure that every person is mindful of the indications' definitions but additionally promotes a culture of security within the useful source work environment. By prioritizing normal upkeep and updates, companies can create a much safer environment and boost the total efficacy of their forklift safety signs.

Verdict

In final thought, the implementation of best practices for showing forklift vehicle safety indicators is important for improving work environment safety and security in industrial and storehouse environments. By focusing on presence, employing efficient positioning techniques, making certain conformity with policies, and devoting to regular upkeep, companies can dramatically minimize the danger of mishaps. Such measures not only communicate threats successfully but blog additionally cultivate a society of safety that benefits all employees associated with forklift operations.